Specification parameters

| Type | BL-3D-7800 Parameter | |

| Applicable Wire Dia. | Soft material Φ:3.0-8.0mm Hard material Φ:3.0-6.0mm | |

| Bending stroke | 750 mm | |

| Number of control Axis | 7 Axis | |

| Total power | 11.9KW | |

| Power of wire feeding motor | 2.7KW | |

| Power Of wire turning Motor | 2.7KW | |

| Power Of Wire Cuter Motor | 1.0KW | |

| Power Of Angle control Motor | 1.5KW | |

| inner angle control motor power | 1.5KW | |

| outer angle control motor power | 1.5KW | |

| Power Of Pallet control motor | 1.0KW | |

| Maximum wire feeding speed | 90M/min | |

| Wire feeding accuracy | 300mm±0.1mm | |

| Angle accuracy | 90°±0.2° | |

| Input Power | 380V/50Hz/3Ph | |

| Weight | 2500kg | |

| Machine Size(L*W*H) | 4000mm×1800mm×1750mm | |

| Automatic feeder | Maximum load Weight: | 1500KG |

| Diameter of Round Tray | φ1600mm | |

| Input Power | 2.2KW | |

| Weight | 800Kg | |

| Size (L*W*H) | 2100mm*2100mm*1300mm | |

Characteristic description

Reduced Setup Time: Advanced CNC systems in automatic wire forming machine for automotive steel wire frame facilitate quick and easy programming and setup. This reduces the time it takes to switch between different wire-forming jobs.

Improved Production Speed: The ability to perform multiple movements simultaneously, along with the advanced CNC control, leads to higher production speeds. This increased throughput is particularly valuable for high-volume production environments.

Adaptability to Custom Designs: 7-axis CNC wire forming machines can be programmed to create custom wire forms based on specific design requirements. This adaptability is essential for industries with unique or specialized wire form needs.

Automated Tool Changes: Some 7-axis machines come equipped with automated tool changing systems, allowing for rapid switching between different tooling setups. This further reduces setup time and increases overall efficiency.

Enhanced Safety Features: Many 7-axis CNC wire forming machines are equipped with advanced safety features, such as interlocks and sensors, to ensure safe operation. This helps protect operators and prevent accidents.

Optimized Material Usage: The precision of 7-axis machines reduces material waste, leading to cost savings for manufacturers. This is particularly important when working with expensive or exotic materials.

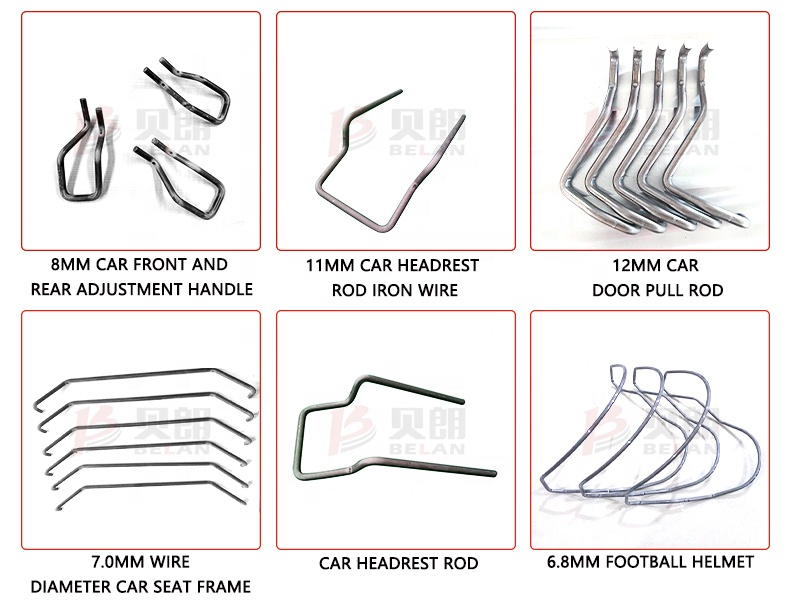

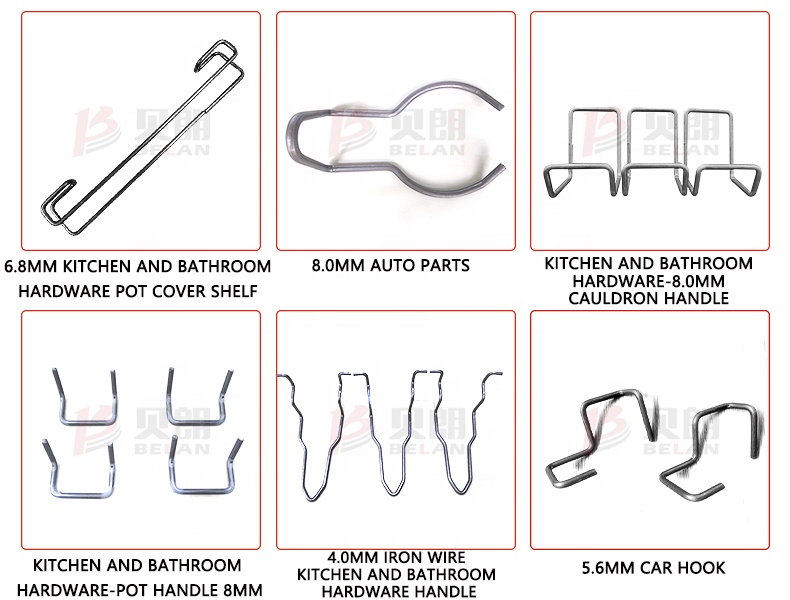

Sample image display

Suitable for production: car seat frames, sunshade frames, car door lock rods, handicraft metal wires, kitchen utensils and tableware brackets, storage cages, supermarket trolleys, supermarket shelves and other wire shaped products