Specification parameters

| Type | Grid machine Parameter |

| Applicable Wire Dia. | W-shaped steel wire:Φ2.0mm Plastic wrapped steel wire:Φ3.0mm |

| Number of control Axis | 28-34Axis |

| Total power | 30KW |

| Weaving station | 10 Axis |

| W Forming Station | 2-4Axis |

| Plastic wrapped steel wire station | 12 Axis |

| Sheep Horn Hook Forming Station 1 | 2-4Axis |

| Sheep Horn Hook Forming Station 2 | 2-4Axis |

| Rough stock of process data | ≥2000 |

| Stabilized power (reference) | 40kw |

| Pneumatic system | 0.5-0.6MPa |

| probe | 4 pc |

| Input Power | 380V/50Hz/3Ph |

| Weight | 6000KG |

| Machine Size(L*W*H) | 11500*4500*2400mm |

Feature and Function

1.Adopting a computer control system, controlled through multi-channel bus.

2. the equipment is formed through servo and pneumatic multi-station bending, and a single station can simultaneously bend multiple angles

3 it can simultaneously bend and shape steel wire, plastic wrapped steel wire, and weave into a grid.

4.Different conventional grid products can be fully automated by switching molds.

5. Modules can be flexibly customized according to different products of customers.

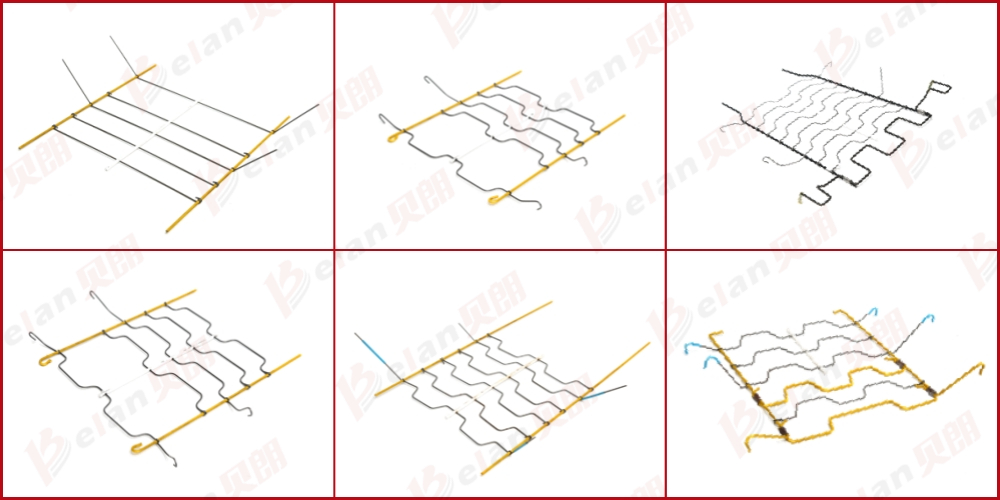

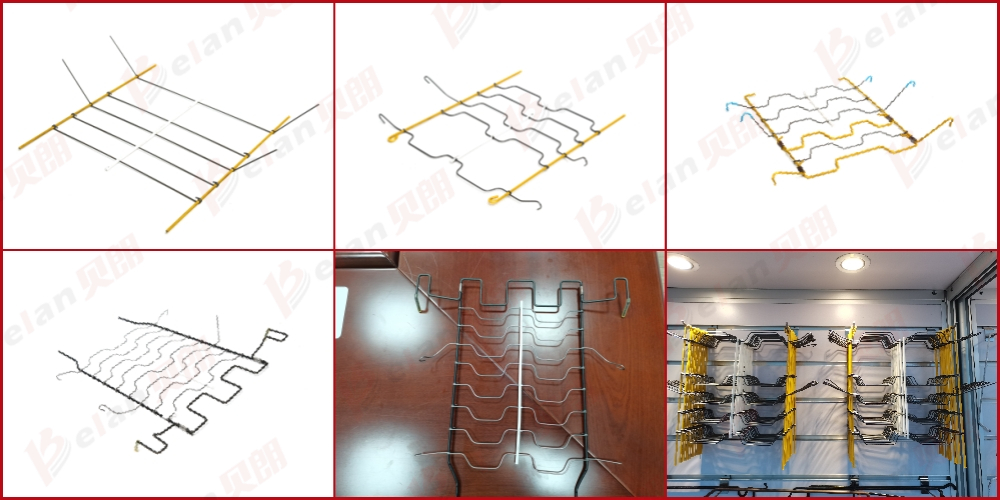

Product samples

Enamel wire bending machine mainly suitable for bending and forming steel wire for car backrest seats, plastic wrapped steel wire, and weaving into grids.