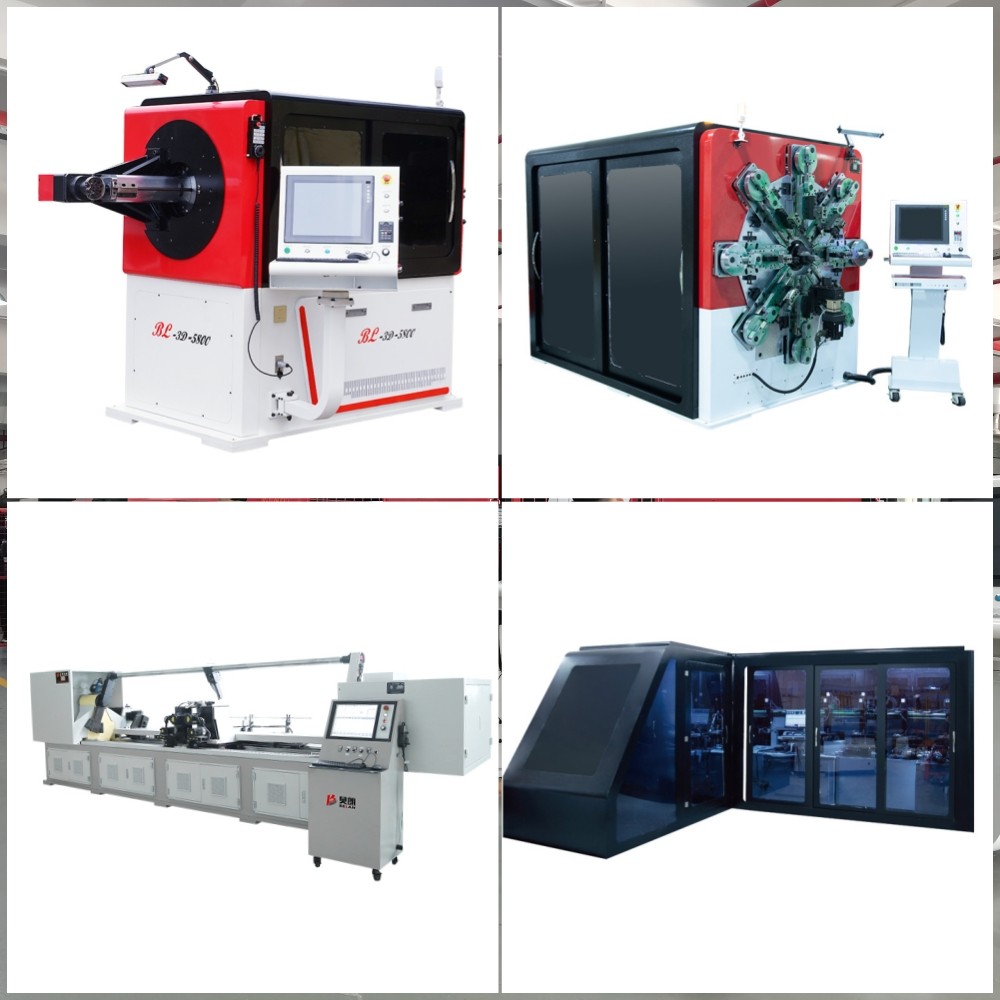

Specification parameters

| Type | BL-2T-12250 Parameter |

| Applicable Wire Dia. | Soft material Φ:1.6-3.5mm Hard material Φ:1.6-2.5mm |

| Bending stroke | 100~400mm |

| No. of Axis | 12 Axis |

| Total power | 12.4KW |

| Power of Wire Feeding Motor | 2.7KW |

| Power of Crank Arm Motor | 1.0KW*4 |

| Power of Free Hand Motor | 0.4KW |

| Power of Curl Motor | 0.4KW |

| Power of Core Bending Motor | 1.0KW |

| Power of Angle Folding Motor | 0.4KW |

| Power of Angle Folding Lifting Motor | 1.0KW |

| Power of Clamping Motor | 1.5KW |

| Power of Rotating Motor | 1.0KW |

| Input Power | 3AC 380V/50HZ |

| Weight of Machine | 1800KG |

| Size (L*W*H) | 2900mm*1800mm*1700mm |

| Maximum load weight of automatic wire feeder: | 200KG |

Characteristic description

Consistency and Quality Control:

The automated nature of CNC car seat foam wire bending machines ensures a high level of consistency in the produced wire forms. This consistency is crucial for industries where quality control is a top priority.

Adaptability to Custom Designs:

These machines can be programmed to create custom wire forms based on specific design requirements. This adaptability makes them suitable for a wide range of industries, including automotive, aerospace, electronics, and more.

Reduced Tool Wear:

These machines use specialized tooling designed for high-volume production. With proper maintenance, the tooling tends to have a longer lifespan compared to manual bending tools.

Data Logging and Reporting:

Many modern double end wire bending machines are equipped with software that allows for data logging and reporting. This feature enables manufacturers to track production metrics, monitor machine performance, and identify areas for improvement.

Overall, a double end wire bending machine is a valuable tool for industries that require precise and efficient wire-forming capabilities, especially when high production volumes are needed. They contribute to increased productivity, improved quality control, and cost-effective production processes.

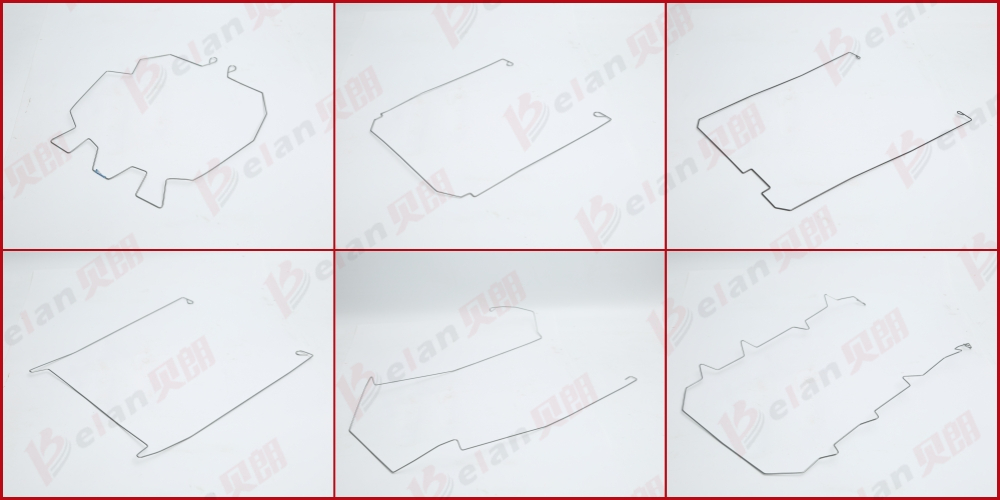

Sample image display

BL-3D-12250 small double-head bending machine is mainly used in the auto parts industry, including car seat wire, car seat parts molding; pet cage parts; kitchen hardware parts; garden tool parts, electronic product molding, toys All kinds of high-precision parts molding, electrical accessories molding, sports equipment accessories molding, stationery accessories molding, instrument accessories molding, instrument accessories molding, hair accessories molding, kitchen and bathroom pendant accessories molding, handicraft molding, supermarket shelf accessories molding, etc. The field of metal wire forming accessories.

Other aircraft propulsion