Specification parameters

| Type | BL-3D-10300 Parameter |

| Applicable Wire Dia. | Soft material Φ:1.0mm-4.0mm Hard material Φ:1.0mm-2.5mm |

| Number of control Axis | 10 Axis |

| Total power | 9.75KW |

| 1 axis arm | 0.75KW |

| 2 axis arm | 0.75KW |

| 3 axis arm | 0.75KW |

| 4 axis arm | 0.75KW |

| 5 axis left and right hand | 0.4KW |

| 6 axis curl | 0.4KW |

| 7 axis feed | 1.8KW |

| 8 axis turntable | 3.0KW |

| 9 axis bending core | 0.4KW |

| 10 axis peeling machine | 0.75KW |

| Maximum wire feeding speed | 80M/min |

| Wire feeding accuracy | 300mm±0.1mm |

| Input Power | 380V/50Hz/3Ph |

Characteristic description

Consistency and Quality Control:

The automated nature of the CNC copper line forming bender machine ensures a high level of consistency in the processed wire. This is crucial for industries where quality control is essential.

Adaptability to Custom Designs:

These machines can be programmed to process wire according to specific design requirements, making them suitable for a wide range of industries.

Data Logging and Reporting:

Many modern Copper Wire Peeling, Peeling, and Bending Machines are equipped with software that allows for data logging and reporting. This feature enables manufacturers to track production metrics, monitor machine performance, and identify areas for improvement.

Overall, a Copper Wire Peeling, Peeling, and Bending Machine is a valuable tool for industries that require precise and efficient wire processing capabilities. They contribute to increased productivity, improved quality control, and cost-effective production processes.

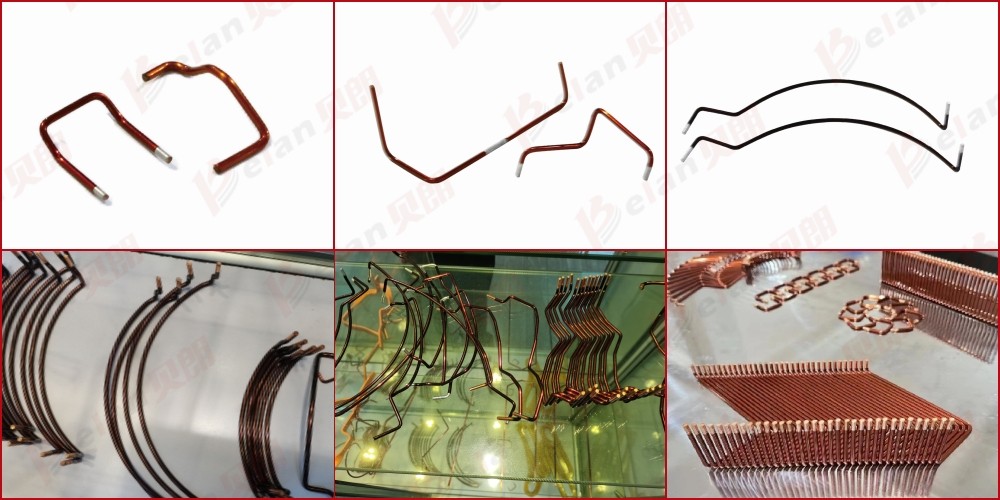

Sample image display