Specification parameters

| Type | BL-3D-10300 Parameter |

| Applicable Wire Dia. | Soft material Φ:1.0mm-4.0mm Hard material Φ:1.0mm-2.5mm |

| Number of control Axis | 10 Axis |

| Total power | 9.75KW |

| 1 axis arm | 0.75KW |

| 2 axis arm | 0.75KW |

| 3 axis arm | 0.75KW |

| 4 axis arm | 0.75KW |

| 5 axis left and right hand | 0.4KW |

| 6 axis curl | 0.4KW |

| 7 axis feed | 1.8KW |

| 8 axis turntable | 3.0KW |

| 9 axis bending core | 0.4KW |

| 10 axis peeling machine | 0.75KW |

| Maximum wire feeding speed | 80M/min |

| Wire feeding accuracy | 300mm±0.1mm |

| Input Power | 380V/50Hz/3Ph |

Characteristic description

1. Flat coil winding machine highly integrated and multifunctional

Straightening + paint removal + vacuuming + tinning + bending one-time forming, multiple processes, completed at one time, saving worry and effort.

2. 10-axis servo precise control

Multifunctional 8-axis servo, combined with a professional operating computer system, ensures the accuracy and stability of product production.

3. Turntable forming flexible and intelligent

The rotation of the turntable not only solves the three-dimensional forming, but also solves the problem that the copper wire needs to be stripped and the tin wire cannot be rotated, which is the biggest highlight of this machine.

4. Small wire forming suitable for both copper and iron

Flat coil winding copper line bender enamel wire bending machine is mainly customized for the bending of enamelled copper wire, and at the same time, it can also bend aluminum wire and iron wire products within the wire diameter range. It is the first choice for bending new energy small copper wire products.

6. Each structural unit completes different tasks, so as to achieve the overall planning of the bending shape of the product

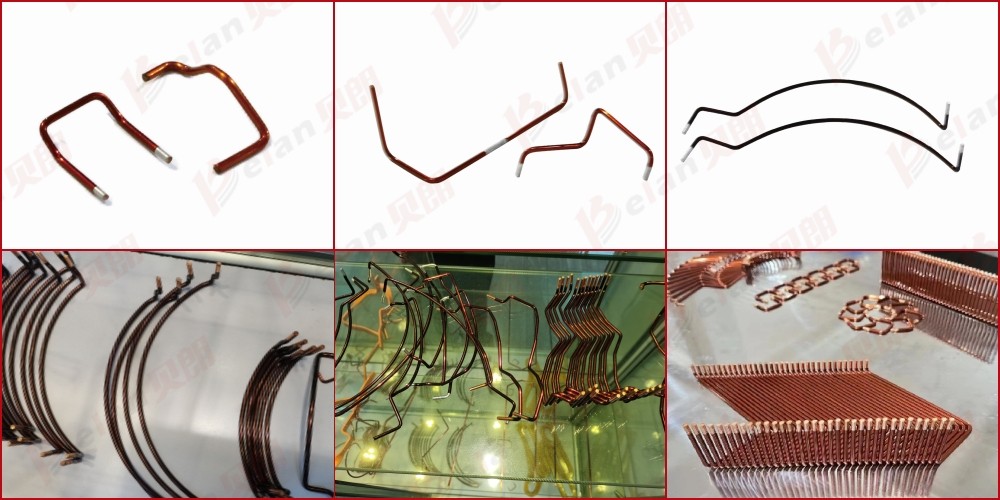

Sample image display