Specification parameters

| Type | BL-TP-30-5E Parameter |

| Applicable Wire Dia. | width Φ:2.0-5.0mm thickness Φ:5.0-30mm |

| Number of control Axis | 12 Axis |

| Total power | 25.7KW |

| Crawler feeding | 1PC |

| Power of wire feeding motor | 4.5KW |

| Power Of wire turning Motor | 2.7KW |

| Servo shear motor motor | 1.0KW |

| Power Of Arm Motor | 2.0KW*8 |

| Power Of Curl Motor | 1.5KW |

| Angle accuracy | 90°±0.2° |

| Input Power | 380V/50Hz/3Ph |

| Weight | 3800KG |

| Maximum load weight of automatic wire feeder: | 1000KG |

| Machine Size(L*W*H) | 2800*2100*2000mm |

| Site occupation: | length 6800mm * width 2500mm |

Characteristic description

A Copper Aluminum Bar Bending Machine is a specialized piece of equipment designed to bend copper and aluminum bars into various shapes and angles. These machines offer several advantages in industries that work with copper and aluminum bars. Here are some of the key advantages:

Cost-Effective Production:

By automating the bending process, these machines can significantly reduce labor costs. Additionally, the high precision and repeatability of these machines help minimize material waste.

Complex Geometries:

Copper Aluminum Bar Bending Machines excel at producing bars with complex geometries that would be extremely challenging or impossible to achieve through manual bending methods.

Consistency and Quality Control:

The automated nature of these machines ensures a high level of consistency in the bent bars produced. This consistency is crucial for industries where quality control is a top priority.

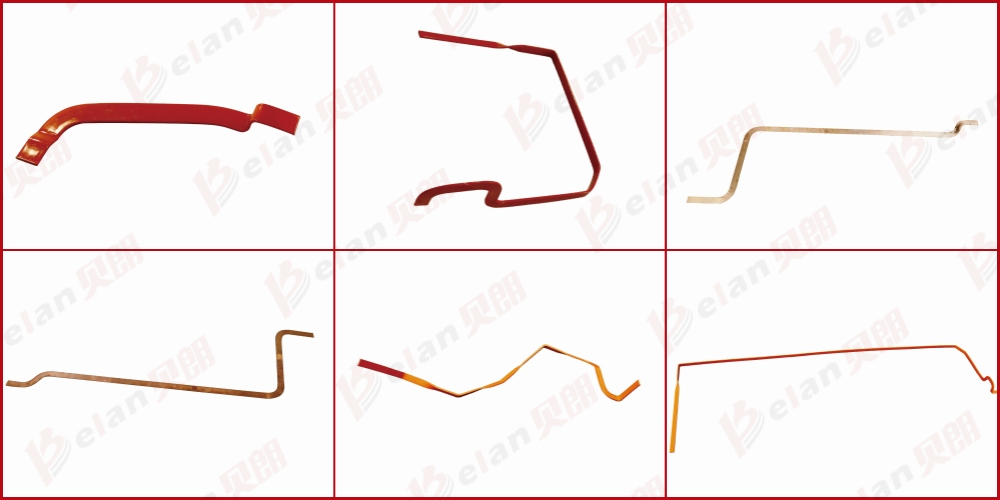

Sample image display