parameter

| Applicable Wire Dia. | width Φ:2.0-8.0mm thickness Φ:8.0-45mm |

| Number of control Axis | 13 Axis |

| Total power | 35.2KW |

| Crawler feeding | 1PC |

| Power of wire feeding motor | 4.5KW |

| Power Of wire turning Motor | 2.7KW |

| Servo shear motor motor | 1.0KW |

| Power Of Arm Motor | 2.0KW*6 |

| Power Of Arm Motor | 5.5KW*2 |

| Power Of Curl Motor | 2.0KW*2 |

| Input Power | 380V/50Hz/3Ph |

| Weight | 3800KG |

| Maximum load weight of automatic wire feeder: | 1000KG |

| Machine Size(L*W*H) | 2800*2200*2100mm |

| Site occupation: | length 6800mm * width 3500mm |

characteristic

1. Thirteen sets of servo motors independently control eight workstations for fast wire feeding, bending, wire transfer, and machine adjustment.

The transmission method of imported servo motors and precision grade gears ensures high accuracy, long service life, and high stability.

3. The tool holder adopts parallel heavy load dual guide sliders, ensuring high rigidity.

4. Simple operation, friendly interface, computer automatic detection of the overall health status and alarm.

5. High precision wire box gear manufacturing process ensures long-term wire delivery accuracy.

6. Meet the bending technical conditions of V8 extrusion busbar. The device can work continuously for 24 hours.

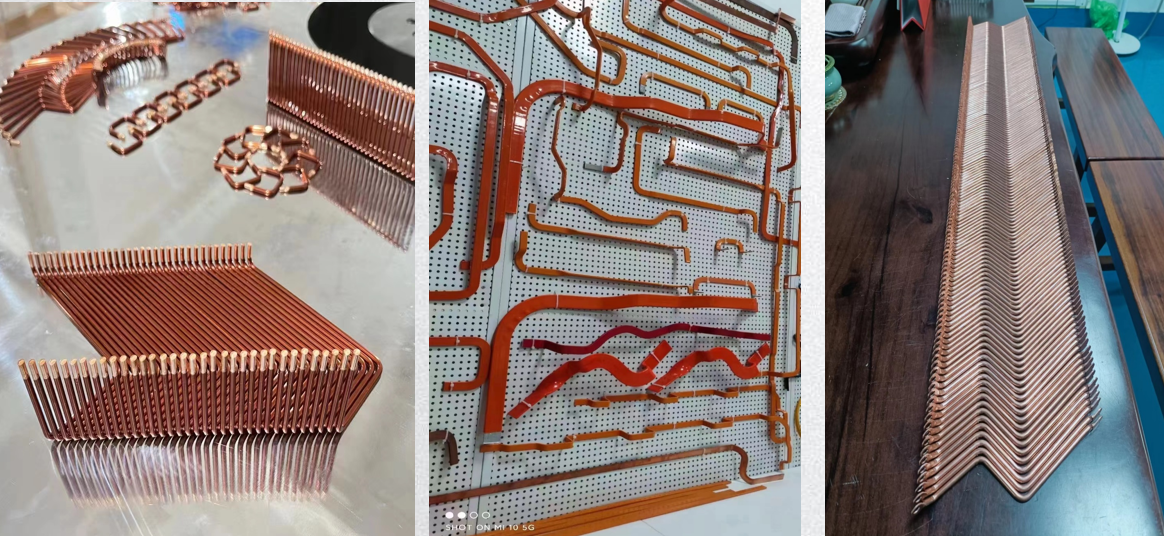

sample