Specification parameters

| Type | BL-TP-45-6E Parameter |

| Applicable Wire Dia. | width :Φ2.0-8.0mm thickness :Φ8.0-45mm |

| Number of control Axis | 13 Axis |

| Total power | 35.2KW |

| Crawler feeding | 1PC |

| Power of wire feeding motor | 4.5KW |

| Power Of wire turning Motor | 2.7KW |

| Servo shear motor motor | 1.0KW |

| Power Of Arm Motor | 2.0KW*6 |

| Power Of Arm Motor | 5.5KW*2 |

| Power Of Curl Motor | 2.0KW*2 |

| Input Power | 380V/50Hz/3Ph |

| Weight | 3800KG |

| Maximum load weight of automatic wire feeder: | 1000KG |

| Machine Size(L*W*H) | 2800*2200*2100mm |

| Site occupation: | length 6800mm * width 3500mm |

Characteristic description

Safety:

Automation reduces the need for manual handling of bars, which can be a safety concern, especially when working with heavy or sharp-edged materials.

Adaptability to Custom Designs:

These machines can be programmed to create custom bent bars based on specific design requirements. This adaptability makes them suitable for a wide range of industries, including automotive, aerospace, electronics, and more.

Reduced Tool Wear:

These machines use specialized tooling designed for high-volume production. With proper maintenance, the tooling tends to have a longer lifespan compared to manual bending tools.

Data Logging and Reporting:

Many modern Copper Aluminum Bar Bending Machines are equipped with software that allows for data logging and reporting. This feature enables manufacturers to track production metrics, monitor machine performance, and identify areas for improvement.

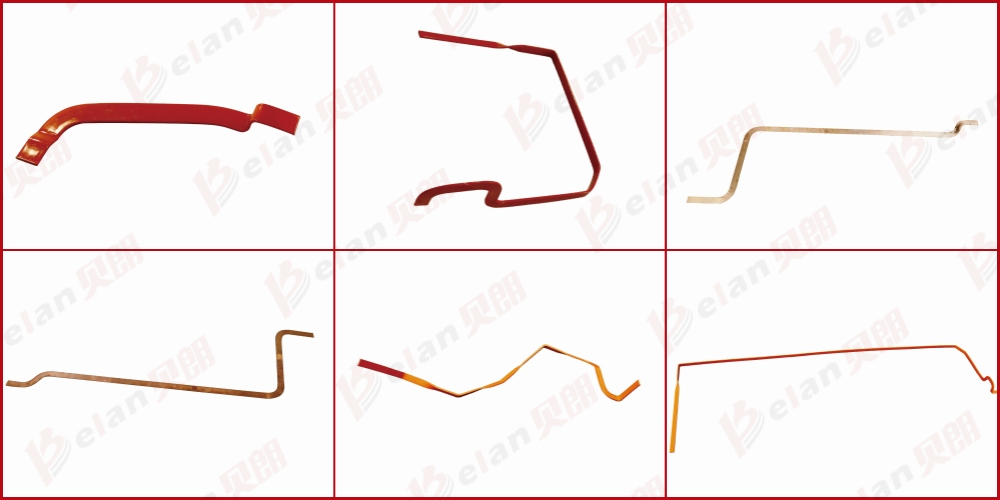

Sample image display

Copper bar bending machine (maximum processing range of copper and aluminum bars: 45mm * 2mm) is a multifunctional special machine that integrates all the functions of 3D bending machine and spring machine. This machine adopts a unique camless and rocker free design, and is independently controlled by multiple sets of servo motors. The Belang copper bar bending machine is widely used for forming conductive bars, new energy battery connection bars, new energy battery modules, copper busbar forming, hard busbar forming, conductive bars, battery connection bars, copper bars Bare row forming, etc. Precise and accurate, fast machine adjustment, stable and reliable.