Specification parameters

| Type | BL-TP-45-6E Parameter |

| Applicable Wire Dia. | width :Φ2.0-8.0mm thickness :Φ8.0-45mm |

| Number of control Axis | 13 Axis |

| Total power | 35.2KW |

| Crawler feeding | 1PC |

| Power of wire feeding motor | 4.5KW |

| Power Of wire turning Motor | 2.7KW |

| Servo shear motor motor | 1.0KW |

| Power Of Arm Motor | 2.0KW*6 |

| Power Of Arm Motor | 5.5KW*2 |

| Power Of Curl Motor | 2.0KW*2 |

| Input Power | 380V/50Hz/3Ph |

| Weight | 3800KG |

| Maximum load weight of automatic wire feeder: | 1000KG |

| Machine Size(L*W*H) | 2800*2200*2100mm |

| Site occupation: | length 6800mm * width 3500mm |

Characteristic description

A copper bar bending machine is a specialized piece of equipment designed to bend copper bars into various shapes and angles. It is commonly used in industries that require copper bars for electrical applications, such as power distribution, electrical panels, and grounding systems. Here is a description of a typical copper bar bending machine:

Frame and Structure:

The machine is built on a sturdy frame made of high-quality materials like steel to ensure stability and durability.

Bending Mechanism:

The bending mechanism consists of a set of precision-engineered rollers or dies that apply force to the copper bar, causing it to bend according to the desired shape or angle.

Control System:

Modern copper bar bending machines often come equipped with a user-friendly control panel or interface. This allows operators to input specific bending parameters, such as angle, radius, and length.

Motor and Drive System:

The machine is powered by an electric motor that provides the necessary force to bend the copper bars. The motor is connected to a drive system that transfers power to the bending mechanism.

Adjustable Rollers or Dies:

The machine typically features interchangeable rollers or dies that can be adjusted to accommodate different sizes and thicknesses of copper bars. This allows for versatility in the types of bends that can be achieved.

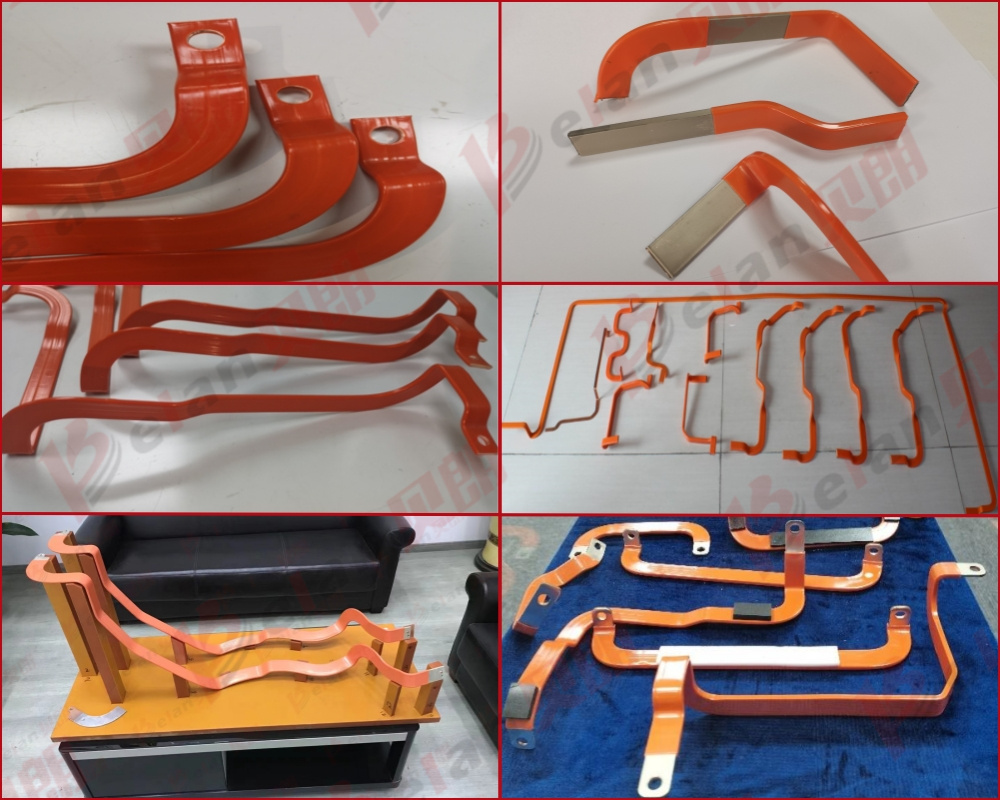

Sample image display

Hard exhaust electric control flat copper wire bending machine (maximum processing range of copper and aluminum bars: 45mm * 2mm) is a multifunctional special machine that integrates all the functions of 3D bending machine and spring machine. This machine adopts a unique camless and rocker free design, and is independently controlled by multiple sets of servo motors. The Belang copper bar bending machine is widely used for forming conductive bars, new energy battery connection bars, new energy battery modules, copper busbar forming, hard busbar forming, conductive bars, battery connection bars, copper bars Bare row forming, etc. Precise and accurate, fast machine adjustment, stable and reliable.