parameter

| Type | BL-TP-45-6E Parameter |

| Applicable Wire Dia. | width Φ:2.0-8.0mm thickness Φ:8.0-45mm |

| Number of control Axis | 13 Axis |

| Total power | 35.2KW |

| Crawler feeding | 1PC |

| Power of wire feeding motor | 4.5KW |

| Power Of wire turning Motor | 2.7KW |

| Servo shear motor motor | 1.0KW |

| Power Of Arm Motor | 2.0KW*6 |

| Power Of Arm Motor | 5.5KW*2 |

| Power Of Curl Motor | 2.0KW*2 |

| Input Power | 380V/50Hz/3Ph |

| Weight | 3800KG |

| Maximum load weight of automatic wire feeder: | 1000KG |

| Machine Size(L*W*H) | 2800*2200*2100mm |

| Site occupation: | length 6800mm * width 3500mm |

describe

The BL-TP-45-6E copper bar bending machine adopts a Taiwanese computer control system and a servo motor imported from Japan, which is convenient, fast, high-speed, and high-precision for operation.

2. It is divided into eight workstation shafts, wire feeding shafts, spindle shafts, and winding crankshafts (optional accessories), with 13 shafts capable of synchronous operation. Eight station axis control)/group sliding seat, which can freely control the forward and backward movement or linkage of each station.

3. The wire feeding system is vertically installed at the back of the machine, using tracked wire feeding to reduce mold replacement. The length of the wire feeding is accurately controlled by a computer, with a minimum wire feeding unit of 0.01mm. Features: wear resistance, minimal noise, and high synchronization accuracy with eight workstations and rotating spindles. The spindle can rotate in both positive and negative directions. The curling device is installed on the sliding seat and can achieve multiple turns of forward and reverse rotation.

4. The position, wire feeding length, production speed, and production quantity of each axis are displayed on the screen, and program data can be edited and modified online, making debugging very convenient and fast.

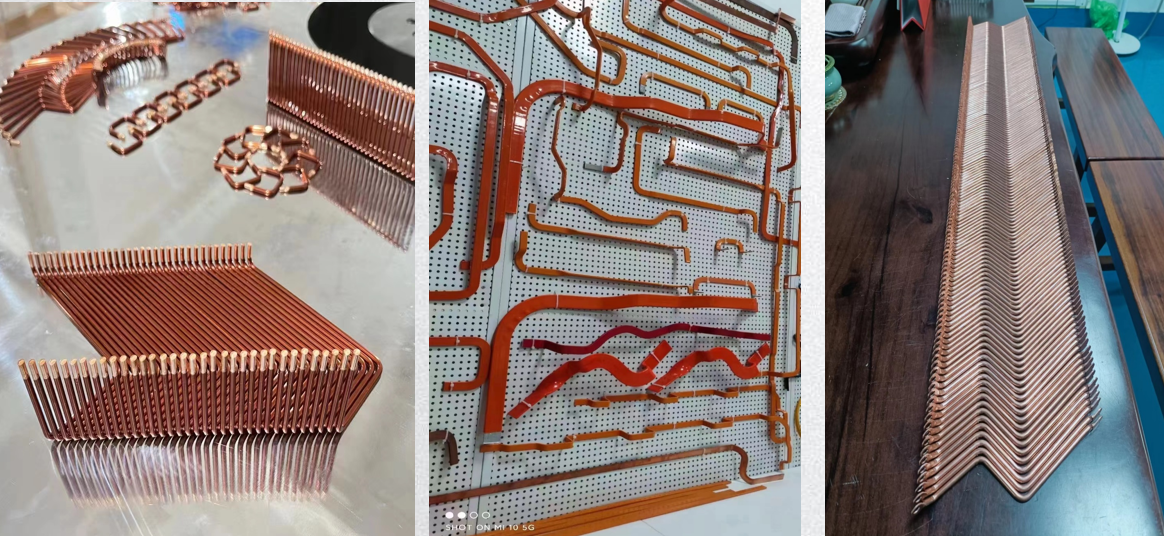

5. The BL-TP-45-6E copper bar bending machine can produce copper and aluminum bars for new energy vehicles and other industries, and is also suitable for various irregular springs such as tension springs, compression springs, tower springs, double torsion springs, flat springs, etc. It can be applied to precision springs required in industries such as lighting, electronics, toys, home appliances, sports equipment, and automobiles.

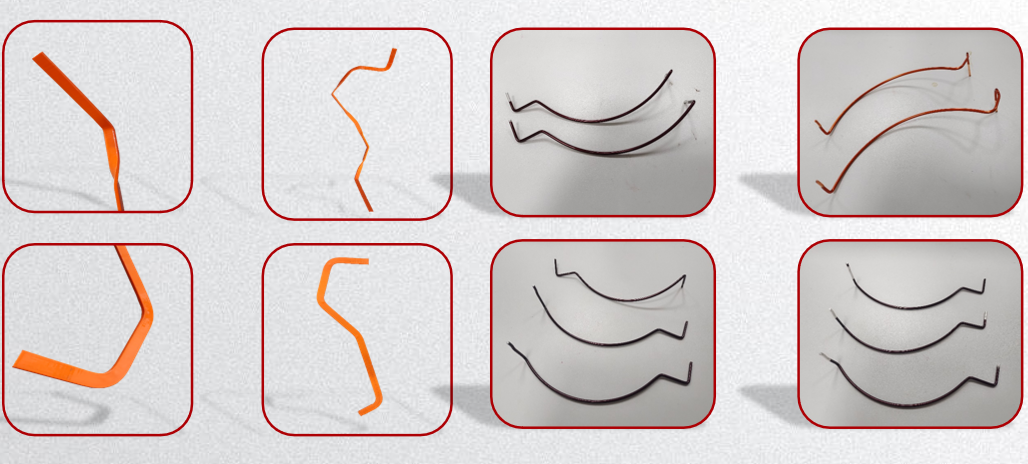

sample

We use our own and third-party cookies to personalize content and to analyze web traffic. Read more about cookies