Specification parameters

| Type | Grid machine Parameter |

| Applicable Wire Dia. | W-shaped steel wire:Φ2.0mm Plastic wrapped steel wire:Φ3.0mm |

| Number of control Axis | 28-34Axis |

| Total power | 30KW |

| Weaving station | 10 Axis |

| W Forming Station | 2-4Axis |

| Plastic wrapped steel wire station | 12 Axis |

| Sheep Horn Hook Forming Station 1 | 2-4Axis |

| Sheep Horn Hook Forming Station 2 | 2-4Axis |

| Rough stock of process data | ≥2000 |

| Stabilized power (reference) | 40kw |

| Pneumatic system | 0.5-0.6MPa |

| probe | 4 pc |

| Input Power | 380V/50Hz/3Ph |

| Weight | 6000KG |

| Machine Size(L*W*H) | 11500*4500*2400mm |

Feature and Function

Mobility and Portability:

Depending on the specific grid machine and its intended use, it may be designed for stationary operation within a workshop or have features that allow for mobility and easy relocation.

Maintenance and Serviceability:

A well-designed car seat frame mesh bending machine will have provisions for easy maintenance, with access points for lubrication, adjustments, and replacement of worn components.

Customization and Programming:

Some advanced models may offer programmable features, allowing for the creation of custom car seat frame mesh designs based on specific

automotive requirements.

Car seat frame mesh bending machines play a vital role in the automotive industry, enabling the fabrication of precisely shaped metal frames that serve as the foundation for comfortable and supportive car seats. They come in various sizes and configurations to suit different production needs, greatly enhancing the efficiency and accuracy of car seat frame production.

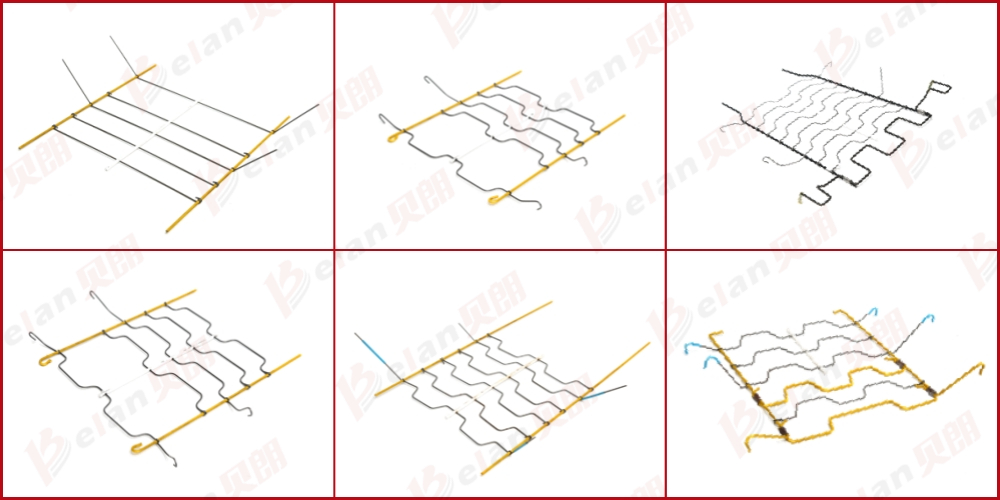

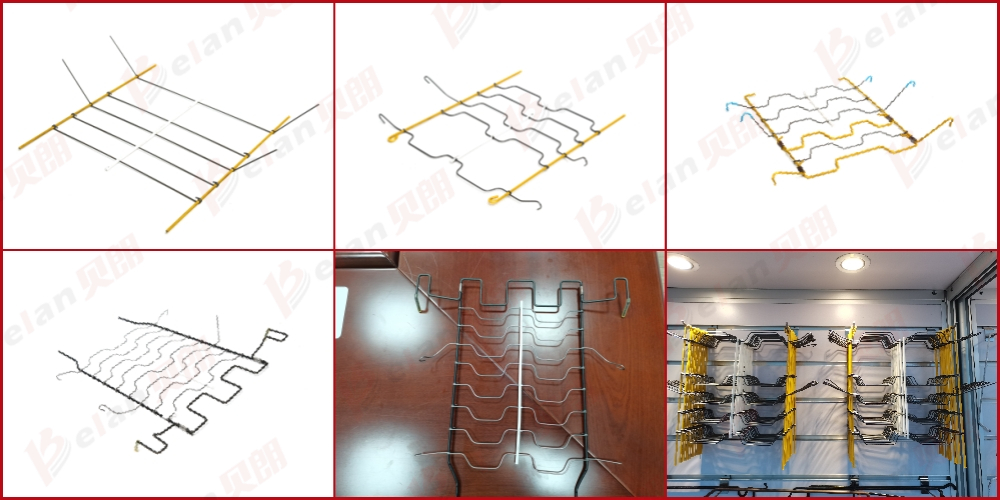

Product samples

Automotive stencil bending machine mainly suitable for bending and forming steel wire for car backrest seats, plastic wrapped steel wire, and weaving into grids.